The blacksmith’s handicraft of Uzbekistan in the city of Bukhara is considered one of the oldest because from the very beginning the man was engaged in metal processing. In the 10th century, Abu Rayhon Beruni mentioned in his works about the skill of the blacksmiths of the city of Bukhara. Earlier they were engaged in the manufacture of damask sabers and knives, medical instruments, manicure, fitters and sewing accessories, which were valued among the merchants of the Great Silk Road.

Currently, traditional craft knives, scissors, sabers, hoes and special tools for other artisans are being created by the Bukhara craftsmen. Local masters used about 40 kinds of drilling tools. In Bukhara, 32 types of metal products.

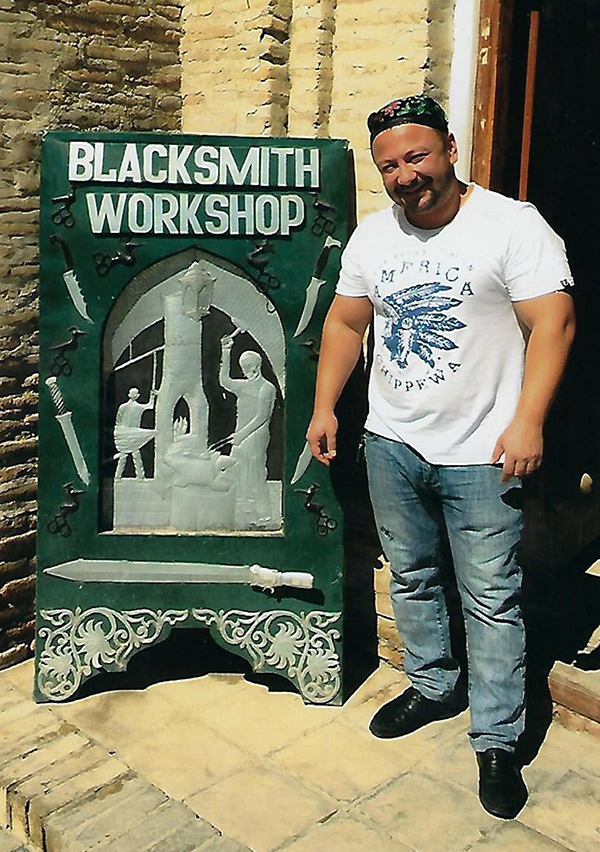

I am a nationally and internationally recognized master of Uzbek traditional blacksmithing. For many years, I have operated my private blacksmith workshop in Bukhara, Uzbekistan, specializing in making knives, daggers, and swords perfectly in accordance with the Bukhara traditional techniques, following in the footsteps of the master of previous generations. My work has won major national awards and has been featured at major international art exhibitions. My work has been praised for publication in major and professional media. I am a member of Hun-Armand, the national association of artisans, craftsmen, and folk artists of Uzbekistan, which requires outstanding achievements of its members as judged by nationally recognized experts in their respective field. My work in the field of traditional Uzbek blacksmithing has been recognized as a contribution of major significance to this field by nationally and internationally recognized experts in this field. My consistent track record of accomplishment in the field of traditional Uzbek blacksmithing clearly demonstrates that I am one of the small percentages who has risen to the very top of the field. For those reasons, I believe that I fully qualify for the classification as an alien of extraordinary ability.

Bukhara has been the main spiritual, cultural and economic center of Central Asia since ancient time. Blacksmithing trade was always considered respected and prestigious. Traditionally, blacksmiths were even believed to have magical and healing powers. The blacksmith was called the king of trades because of his ability to create his own tools. I belong to a family of well-known blacksmiths, who for several centuries have been making knives, dagger, and swords. Everything what I know I learned from my father, the famous Bukharian blacksmith and knife maker, Gaybullo Radjabov. Uzbek knives have peculiarities to the culture of Central Asia. Therefore, I was brought up in the spirit of creativeness and was passionately involved in process of learning and practicing traditional patterns.

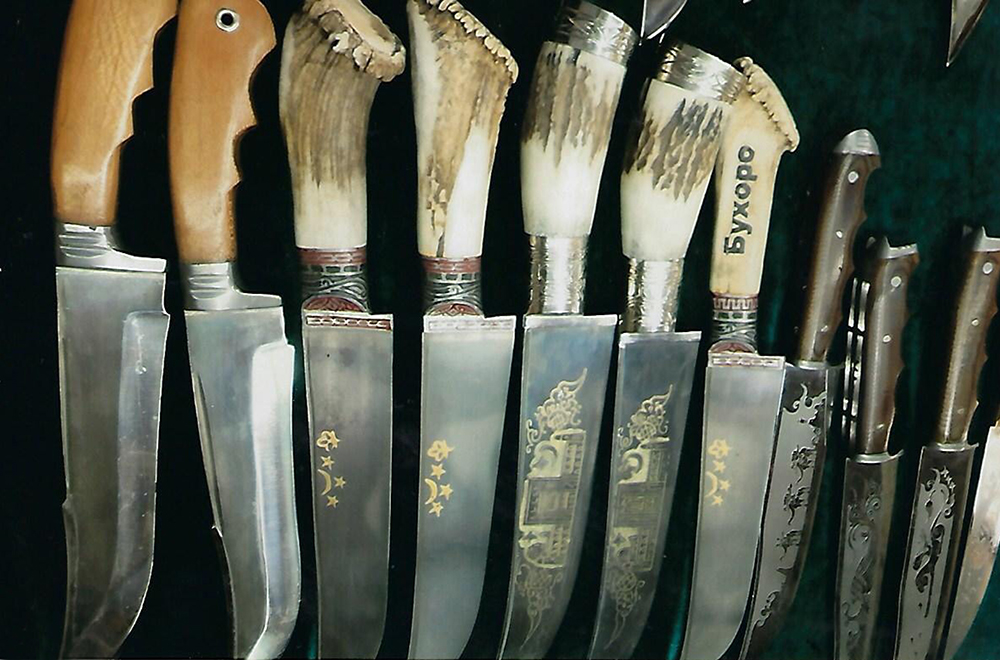

Knife manufacturing on the territory of Uzbekistan has been known since the ancient times. These days, hand-made knives carry unique artistic value, especially in the hunting community. Hunters have a special connection with instruments and tools which they use. Over the ages, such tools have been adorned with beautiful patterns. Even in modern days, when purchasing a knife for hunting or fishing, the product of choice must be not only of lasting performance and quality but also have an attractive design that gives the owner a sense of pride.

I conducted research and studied literature, learning the ancient techniques and styles of the various school of blacksmithing. I made my knifes using my own design and traditional technique. Throughout years of my studies and work as a blacksmith, I was able to revive certain element of this traditional Uzbek craft and to find the optimum balance between modern technologies and the traditional Bukhara techniques of blacksmithing. My goal is not to just copy the ancient originals, but to add my own invented elements in order to enrich and develop the traditional blacksmithing art. I pay significant attention to traditional forms and shapes. I prefer to make Uzbek pichoqs (knives) according to traditional Uzbek techniques used by masters from previous generations. I like to work with low carbon steel, which makes the blade more flexible but hard enough for various purposes. The traditional of my family was not to stop on achievements and go further. I always try to follow this tradition. I have a big library which has a lot of books about techniques used by blacksmiths from all over the world. My goal has always been to further creative develop blacksmithing techniques. I believe that I have made an original contribution of major significance to the field of Uzbek traditional blacksmithing by virtue of reviving the techniques of the traditional Uzbek school of blacksmithing and by blending them with the modern technologies and my invented elements.

To make the blades of knives, I use high quality hard and stainless steels in combination. With alloy of tungsten carbide and cobalt carbide in the proportion of 90 to 10. For the handles of knives, I use horn, wood, bone and metal plates ( steel, copper, silver, and brass). The main tools for my work are a good forge, anvil, sledgehammers, clamps, various hummers, various saws, grinder, tongs, and sandpaper.

In order to make each blade, the correct size of steel should be chosen. Hard steel with a large amount of carbon is chosen for cutting edge of the blade. Different types of steel are chosen depending on the intended use of the blade. For example, hard steel is the good edge of a knife. However, it is not good to use it for the entire body of the blade. The steel with a low amount of carbon is soft steel, a bit flexible. When it joins with hard and brittle steel, it strengthens the blade. If the blade is too soft, it will not cut well. However, if it is too hard it can easily chip or break.

By combining the hard steel and soft steel, the sharpness improves and the knife is strong enough. To make hard steel harder, I use an alloy of tungsten carbide and cobalt carbide. This material was invented at the end of the 19th century. Adding this alloy makes the blade perfectly hard. However, at the same time, the forging takes much more time. The knife made using this technique will not require sharpening in the future. During the forging process take a piece of hard steel and joined it with a piece of soft steel and heat to 1200 Degrees Celsius. Then, they are hammered together into the rough shape of the blade. During forging process, the sparks fly out and iron oxide and other impurities are removed, improving the quality of the steel. The forged blade is once again put into the hearth, heated and hammered to the rough shape and thickness of the finial blade. The particles inside the metal become further refined, thereby strengthening the blade and making a longer lasting edge.

While paying careful attention to the heat of the hearth, any iron oxide on the surface of the blade is removed and the surface of the blade is smoothed. During this process, the metal particles are removed even further, improving the durability of the blade. ln order to homogenize the structure, the blade is heated at a low temperature and then placed in straw ash to cool. By doing so, any stress and distortions are taken out of the blade and it is further strengthened. A grinder is used to bring the current shape of the blade to the correct size. Forgen blades have dark spots of iron oxide on the surface. If they left on the blade, then the heat will not be eventually spread across it. By polishing the surface and removing black spots, the hardenability of the blade is increased. In order to harden blade, I head it and then quickly put it into water or oil to immediately cool it. This step improves the longevity of the cutting edge. However, if the blade is heated too much, the steel becomes brittle and the cutting edge worsens. Therefore, the temperature is strictly controlled. Hardened blades without any further treating are brittle, so they are heated until they reach the correct level of softness. By doing so, become harder and chip and more practical. When the blade is hardened, the steel shrinks slightly which produces some warpage. The blade is straightened by using a copper mallet to strike the blade and correct its shape doing courses the blade to become easier to use perfectly straight. A revolving whetstone is used to hone the blade. However, the friction of whetstone causes heat which can be softened already hardened blade.

Therefore, water is continuously poured over the blade and the whetstone while the blade is sharpened. Also, during this process, any black spots that appeared during the tempering process are removed. Any cutting marks that are left on the surface of the blade make the surface of the blade not perfect. In order to avoid these conditions, sandpaper is used to polish the blade and to make it shiny like a mirror. This step creates more resistant and hygienic knife. Attaching the handle is the last step is knife making. In order to prevent any water entering into the insertion point of the handle and causing rust, epoxy resin is inserted and the blade is affixed. Making the blade in this process and considering each step in its making, allow me to create knives that never break, never bend and cut very well. My knives differed in their shape, material, decoration, and technique used in their making. There are various knifes blades I forge from high-quality steel. My favorite shape of the blade is “Tolbagri” Pichok (knife), which looks like a willow leaf. Others have an almond shape called “Kamalak” pichok, which has a canal along the upper edge of the blade.

My achievements in the field of traditional Uzbek blacksmithing have earned me many professional honors. I am a member of Hunarmand, the Uzbek national professional association of skilled craftsmen and artisans. This is a professional association of traditional folk artists in various fields that promote the development of traditional folk arts in Uzbekistan and raises awareness about our rich cultural heritage. It is open only to highly skilled masters who are among the best in their field. Hunarmand Association requires outstanding achievements of its member, as judge by nationally or internationally recognized experts in the respective field of folk art. I was accepted to the Association bade on my outstanding achievements in the field of traditional Uzbek blacksmithing, as judged by nationally recognized experts in the field of traditional Uzbek miniature painting. My work in this field has won major national awards and has been featured at major international art exhibitions. My work has been praised in publication in major and professional media, including newspaper “Buxoroi Sharif”, Uzbekistan major newspaper in national circulation.

The excellence of my work has been recognized internationally. In 2016, I was awarded the Seal of Excellence award for my handicraft product in Asia-pacific Region by UNESCO for demonstrating excellence and setting an example of high quality in my craftsmanship. The Seal of Excellence was established to encourage craft-workers to use traditional skills and materials. The Seal also seeks to ensure the continuation of the traditional knowledge and the preservation of cultural diversity in the region. At the same time, it serves as a quality recognition tool to which promotes both traditions and quality innovation in the global craft market. When assessing the products, the experts review their excellence, innovation authenticity, marketability, eco-friendliness and social responsibility, and their award to me was a definite recognition of these qualities in my craft.

I displayed my artwork at many major national and international exhibitions and craft fairs. In 2017, I displayed my knives at “Oriental Bazaar” exhibition, held in Tashkent, Uzbekistan. In 2016, I was one of the exhibitors of the 15th annual international festival “ Silk and Spices” in Bukhara, Uzbekistan. This is a major international cultural festival celebrating the national arts and craft of Uzbekistan. In 2015, I displayed my work at Art Paris Fair in Paris, France. In 2014, I displayed my work at World Fine Art Festival (VERA) in Lisbon, Portugal. In 2012, I displayed my art at the 35th interregional Exhibition-Fair “ Souvenirs, Presents, Ornamentations” in Moscow, Russia. In 2009, I have displayed my work at Moscow International Exhibition “ The Golden Hands of Masters” in Moscow, Russia. At all of these prestigious artistic exhibitions and craft showcases, my artwork was well received and appreciated by experts and buyers alike.